A Welding Procedure Specification (WPS) is the formal written document describing welding procedures, which provides direction to the welder or welding operators for making sound and quality production welds as per the code requirements . The purpose of the document is to guide welders to the accepted procedures so that repeatable and trusted welding techniques are used. A WPS is developed for each material alloy and for each welding type used. Specific codes and/or engineering societies are often the driving force behind the development of a company's WPS. A WPS is supported by a Procedure Qualification Record (PQR or WPQR). A PQR is a record of a test weld performed and tested (more rigorously) to ensure that the procedure will produce a good weld. Individual welders are certified with a qualification test documented in a Welder Qualification Test Record (WQTR) that shows they have the understanding and demonstrated ability to work within the specified WPS.

Introduction[edit]

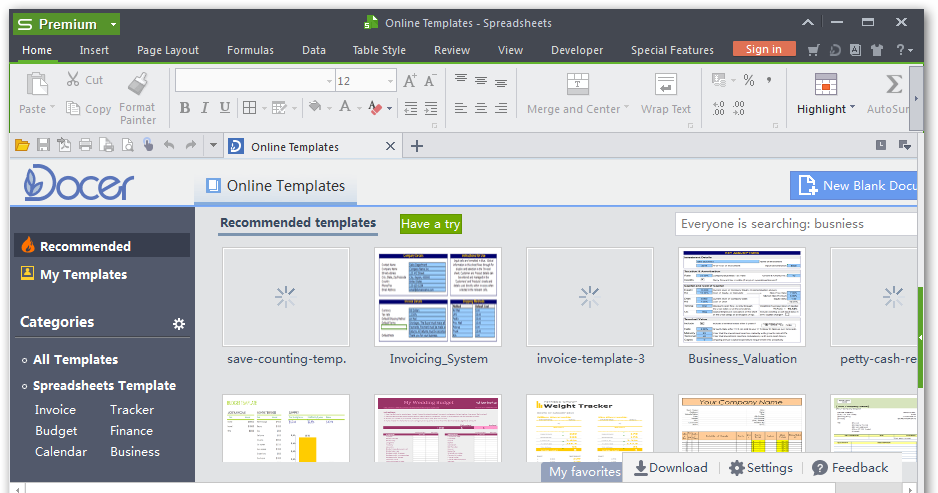

Classical Chinese style PowerPoint template download. PowerPoint Templates Free Download. If infringement, please contact us, we will be deleted within 3 days. Unlimted downloads of Library; Ad-Free and Cross-Platform; 1 GB WPS Cloud Storage; Sign in. All (89) Presentation (76) Writer (7) Spreadsheet (5) Download. Medical Colorful PPT Template. Health Medical Template. Five Timelines chart. Four Procedures chart67. WPS Office Free; WPS Office. Free Architect PowerPoint Template. Free Architect PowerPoint Template is a presentation design featuring an Architect in the cover slide. This presentation template can be used to prepare proposals and PPT presentations on architectural projects, engineering, project management, architectural design, or as a template to be used by architecture studios and firms.

Presentation templates will save you time while you won't have to compromise on quality. They make you look instantly professional. Even the simplest template will convey a tidy, clean and professional image. Care for details is always much appreciated, even if you don't fully realise it. Plus, presentation templates are super easy to use. Free Downloads ANSI Z49.1:2012, Safety in Welding, Cutting, and Allied Processes. The American Welding Society's Board of Directors has decided that ANSI Z49.1 should be distributed freely, as it is an important voluntary welding safety and health standards document.

The following are definitions for WPS and PQR found in various codes and standards:

According to the American Welding Society (AWS), a WPS provides in detail the required welding variables for specific application to assure repeatability by properly trained welders. The AWS defines welding PQR as a record of welding variables used to produce an acceptable test weldment and the results of tests conducted on the weldment to qualify a Welding Procedure Specification. For steel construction (civil engineering structures) AWS D1.1 is a widely used standard. It specifies either a pre-qualification option (chapter 3) or a qualification option (chapter 4) for approval of welding processes.[1]

The American Society of Mechanical Engineers (ASME) similarly defines a WPS as a written document that provides direction to the welder or welding operator for making production welds in accordance with Code requirements.[2] ASME also defines welding PQR as a record of variables recorded during the welding of the test coupon. The record also contains the test results of the tested specimens.

The Canadian Welding Bureau, through CSA Standards W47.1,[3] W47.2[4] and W186,[5] specifies both a WPS and a Welding Procedure Data Sheet (WPDS) to provide direction to the welding supervisor, welders and welding operators. The WPS provides general information on the welding process and material grouping being welded, while the WPDS provides specific welding variables/parameter/conditions for the specific weldment. All WPS and WPDS must be independently reviewed and accepted by the Canadian Welding Bureau prior to use. These CSA standards also define requirements for procedure qualification testing (PQT) to support the acceptance of the WPDS. A record of the procedure qualification test and the results must be documented on a procedure qualification record (PQR). All PQTs are independently witnessed by the Canadian Welding Bureau.

In Europe, the European Committee for Standardization (CEN) has adopted the ISO standards on welding procedure qualification (ISO 15607 to ISO 15614), which replaced the former European standard EN 288. EN ISO 15607 defines a WPS as 'A document that has been qualified by one of the methods described in clause 6 and provides the required variables of the welding procedure to ensure repeatability during production welding'. The same standard defines a Welding Procedure Qualification Record (WPQR) as 'Record comprising all necessary data needed for qualification of a preliminary welding procedure specification'.[6] In addition to the standard WPS qualification procedure specified in ISO 15614, the ISO 156xx series of standards provides also for alternative WPS approval methods. These include: Tested welding consumables (ISO 15610), Previous welding experience (ISO 15611), Standard welding procedure (ISO 15612) and Preproduction welding test (ISO 15613).

In the oil and gas pipeline sector, the American Petroleum Institute API 1104 standard is used almost exclusively worldwide. API 1104 accepts the definitions of the American Welding Society code AWS A3.0.[7]

WPS is of two types- Prequalified WPS(pWPS) & qualified WPS.

See also[edit]

References[edit]

- ^AWS D1.1/D1.1M: 'Structural welding code - Steel'

- ^ASME Boiler and Pressure Vessel Code section IX: 'Qualification Standard for welding and brazing procedures, welders, brazers and welding and brazing operators', Article II, Section QW-200.

- ^CSA Standard W47.1: Certification of companies for the fusion welding of steel (2009)

- ^CSA Standard W47.2: Certification of companies for the fusion welding of aluminum (2011)

- ^CSA Standard W186: Welding of Reinforcing Bars in Reinforced Concrete Construction (1990)

- ^EN ISO 15607:2005 'Specification and qualification of welding procedures for metallic materials - General rules (ISO 15607:2003)'

- ^API 1104: 'Welding of pipelines and related facilities', parts 3 (Definition of Terms)

List of standards[edit]

- ASME Boiler and Pressure Vessel Code section IX: 'Qualification Standard for welding and brazing procedures, welders, brazers and welding and brazing operators'

- EN ISO 15607: 'Specification and qualification of welding procedures for metallic materials - General rules (ISO 15607:2003)'

- EN ISO 15609: 'Specification and qualification of welding procedures for metallic materials - Welding procedure specification (ISO 15609)', five parts.

- EN ISO 15614: 'Specification and qualification of welding procedures for metallic materials - Welding procedure test (ISO 15614)', 13 parts.

- API 1104: 'Welding of pipelines and related facilities', parts 5 (procedures)

Generate welding procedure specifications (WPS)

including WPS Template

The comprehensive database and process dependant entry system means you arrive at the welding procedure specification (WPS) quickly and easily.

Managing Welding Procedure Qualification Records (WPQR / PQR)

Quickly find the needed WPQR (PQR) Welding Procedure Qualification Record and keep track of the status.

Wps Templates Free Download

Welder qualification and Welder certification management

(e.g. EN 287-1; EN ISO 9606)

Free Wps Office Template Downloads

Keep a constant eye on your welder qualification and welders certification. The current status of a welder's certification can be seen at a glance on the 'traffic light' symbol.

Welding cost calculation

Keep welding costs under control and calculate to meet market requirements.

Compare any calculations with a view to optimizing your weld cost.

Plug-in concept

Following manufacturer plug-ins provide you with welding process data sheets or product information.

- ESAB Welding and Cutting (OK-Handbook)

- Safra (Aluminium + Copper filler metal)

- Linde Gas

- Air Liquide

- PanGas

- Praxair

- Wolfram Industrie

Philosophy

- Don't type - just click

- fast, straightforward, compact and any amount of data

- polish off simple tasks

- the fast track to welding solutions, welding procedure and more

- the WPS program which generates resources

Use the weldassistant ® software because…

- your work, as supervisor or the person accountable, has to be fast and efficient

- you place emphasis on proven, practical solutions

- you want to concentrate more on the core assignments of your work

- you want to gain more time for actual project work by deploying welding procedure software

- you want to fulfill the quality requirements of the EN ISO 3834, EN 1090,EN 15614 etc.

Not all welding procedure software offers the same…

Standards compliant data for parent materials, fillers, gases etc. spare you the tedium of researching printed and online media.

Our new highly praised manufacturer plug-in concept will assist you in the search for suitable filler materials and additives.

By this means, in addition to the 'tabular' information, the manufacturers also provide you with data sheets on their products. Equipped with the most important European languages, you will be well prepared for international business.